Temporary Liquid Protective Film Vi-Pro Liquid Foil

Modern facades and windows are expensive building components that require protection until the completion of the construction process. After the installation of windows and facades, a number of finishing works are carried out on the building, such as plastering, painting, installation of tiles, floors, window sills, where contamination may occur, e.g. glass or window frames with mortar or their scratches. Repairing such damage is often impossible or costly and time-consuming.

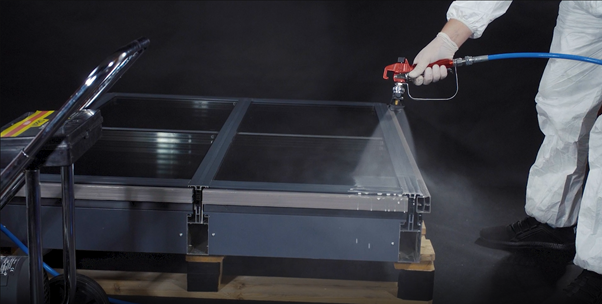

The solution to avoid such problems is to protect the woodwork with a protective Vi-Pro Liquid Foil foil, which can be applied with a roller or by spraying.

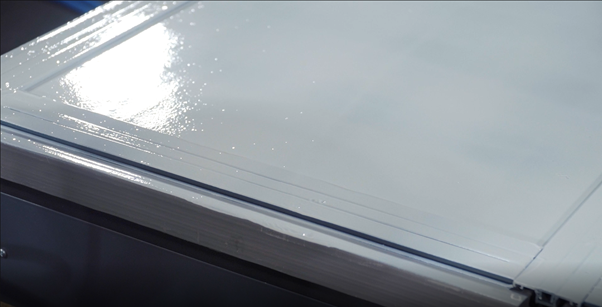

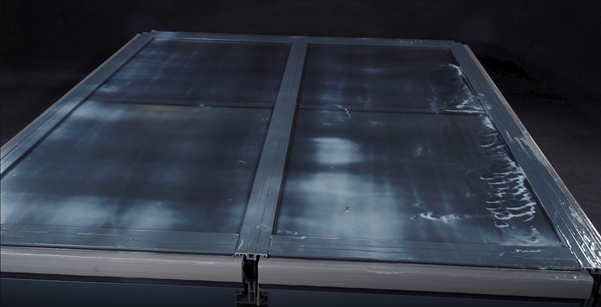

Vi-Pro Liquid Foil is a semi-transparent, water-based, milky-colored, water-based protective coating that can be applied to colored or unstained vertical or horizontal surfaces for temporary protection.

Vi-Pro Liquid Foil can be used for long-term protection on some non-porous surfaces such as: aluminum, standard white PVC, glass, marble or granite surfaces, ceramics, laminated parquet, epoxy coated surfaces, etc. It protects against dirt, painting, scratches, welding spatter, water, moisture and corrosion.

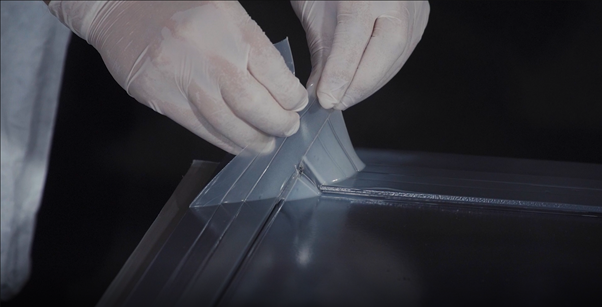

Reduction of the risk of losses and costly repairs, speed of application in relation to standard films, improvement of the company’s image (no complaints), easy removal after the protection period, safety, the product does not adversely affect glass, gaskets or frames, it is compatible with sealants are just some of the strengths of the product .

Other advantages include:

– the water emulsion can be applied to electrostatically painted surfaces

– quick-setting

– easy to peel off

– efficient in use, no waste

– the peelable foil is resistant to various paints and chemicals

– protects against welding burrs

– thixotropic formulation allows application to vertical surfaces

– non-flammable material

– Application tools can be cleaned with water, making cleaning easy and cheap.

It is also worth emphasizing the fact that the product is ecological and safe for the environment, does not affect human health and does not require special disposal.

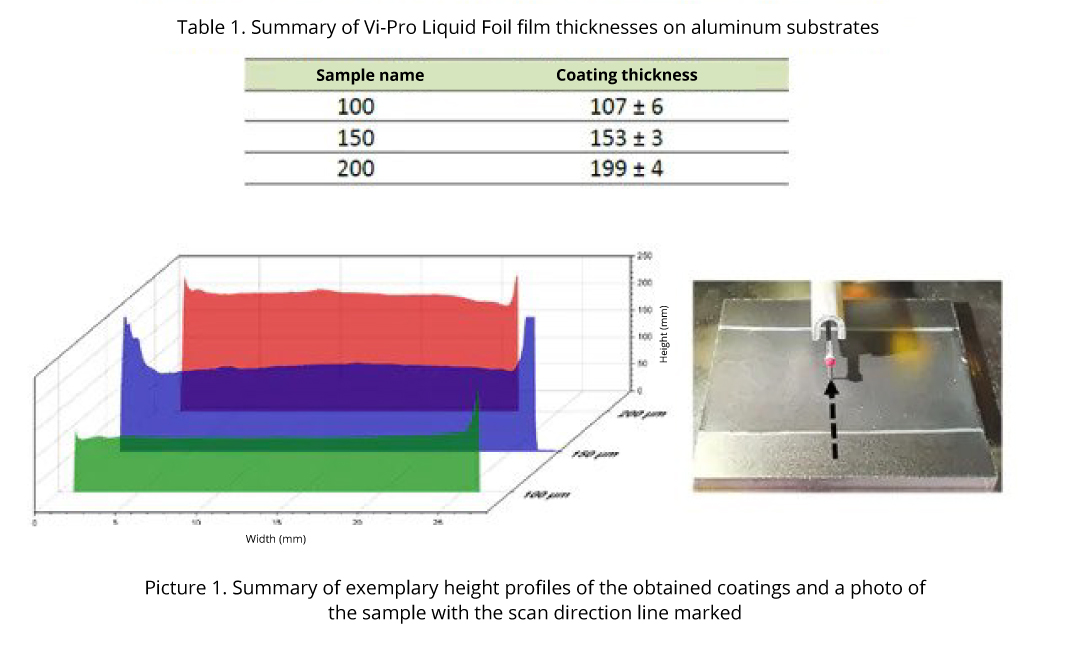

The effectiveness of securing windows and panes with LF foil is confirmed by a series of tests commissioned from specialized laboratories, during which, inter alia, relationship between the thickness of the foil and its tear resistance, i.e. the level of protection it provides.

In addition, we have carried out a series of studies and tests to assess the compatibility of the foil with materials such as anodized and powder coated aluminum, as well as weather silicones used in structural and modular facades.

The key advantage of using LF foil is the comprehensive protection of the structure and the speed of application. Depending on the needs, the foil can be applied with a conventional paint roller or by spraying. To protect larger surfaces and to increase efficiency, we recommend spray application using dedicated pneumatic or electric pumps, which we also have in our offer.