- About us

- Applications

- Structural glazing & weathersealing in building façades

- Bonding applications in ventilated façades

- Insulating glazing

- Window and door manufacturing

- Solar & PV

- Vi-Pro System EPDM

- Balustrades and Glass Point Fixing

- Waterproofing

- Thermoinsulation

- Fire protection of building façades

- Acoustic protection of facades

- General purpose sealants

- Installation Tapes

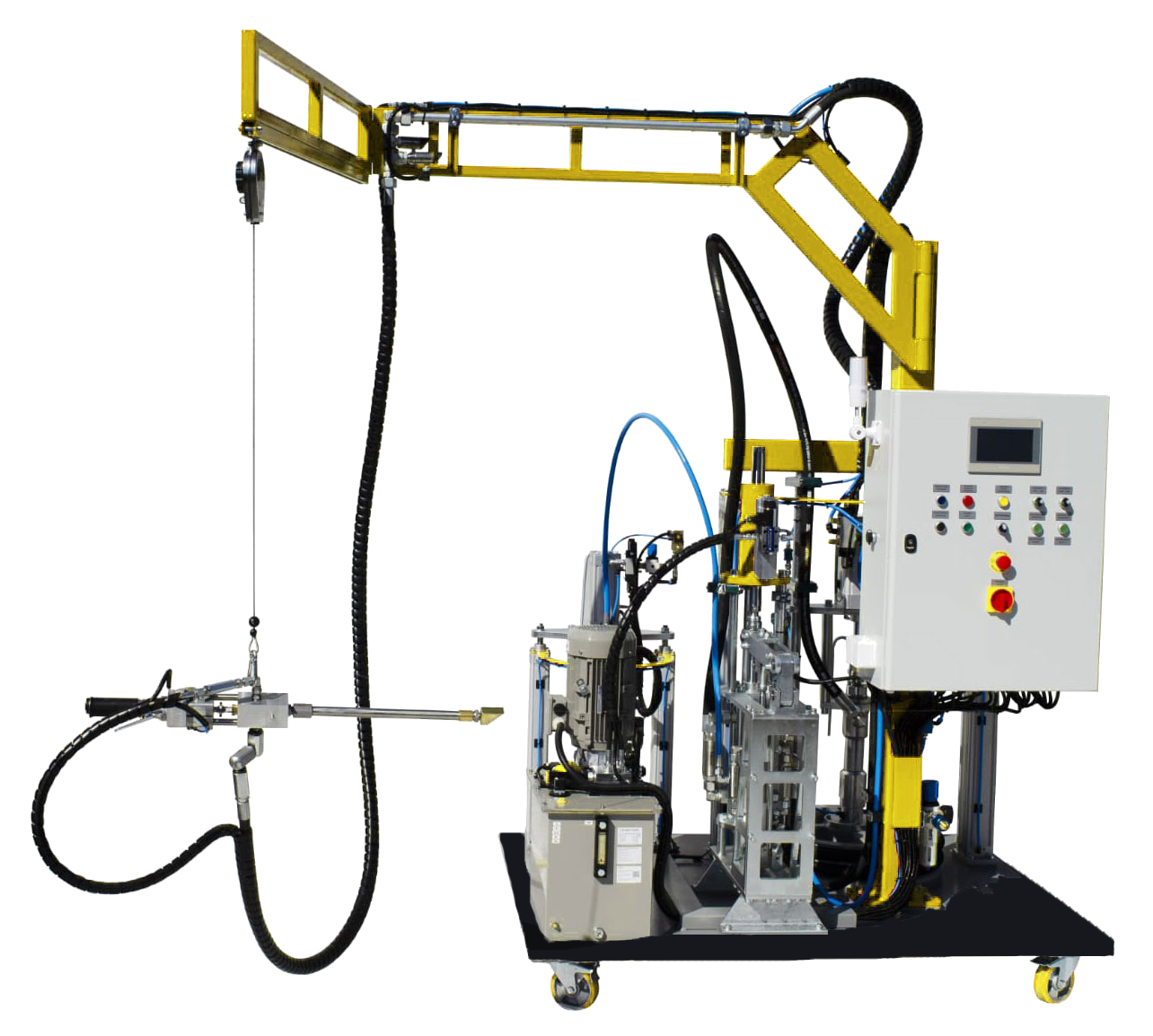

- Tools and Equipment

- Accessories

- Brands

- Solutions

- Technical support

- Contact